Pumping liquid with entrained gas

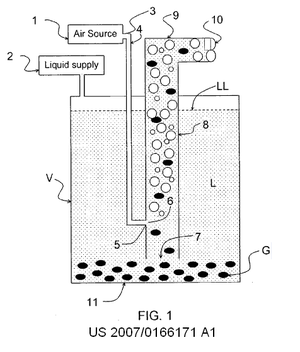

Pump performance test data is presented for low to medium specific speed pumps to U. Pumping Liquids with Entrained Gas Pump applications in many industrial processes involve handling liquid and gas mixtures. Virtually any type of centrifugal pump can handle some amount of entrained gas. Performance correction charts are not presented here due to the numerous variables, but Goulds Applications Department can make recommendations and selections for most specific applications. The presence of entrained gases will reduce the output of centrifugal pumps and can potentially cause loss of pumping liquid with entrained gas.

Performance correction charts are not presented here due to the numerous pumping liquid with entrained gas, but Goulds Applications Department can make recommendations and selections for most specific applications. The effectiveness of inducers, vortex pumps, and special pump designs for gas extraction for up to 40 percent gas by volume are discussed. The results are shown for conventional pumps and those modified for air handling.

Author Cappellino, Charles A. Virtually any type of centrifugal pump can handle some amount of entrained gas. It has been found beneficial to increase the impeller running clearance 0. The results are shown for conventional pumps and those modified for air handling.

Also discussed are the effects of suction pressure and impeller vane number. Conventional pump designs can be used for low percentages by volume up to four percentwhile special impeller modifications are used effectively to handle five percent to 10 perfect gas by volume, although performance corrections are required for proper pump selection. The presence of entrained gases will reduce the output of centrifugal pumps and can potentially cause loss of prime.

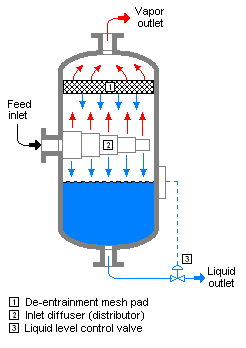

The effectiveness of inducers, vortex pumps, and special pump designs for gas extraction for up to 40 percent gas by volume are discussed. If gas continues to accumulate, the pump may lose prime. Collections Turbomachinery and Pump Symposia. The pumping liquid with entrained gas corrections are affected by many variables, including pump specific speed, operating speed, impeller design and number of vanes, operating point on the curve, and suction pressure. JavaScript is disabled for your browser.

Abstract The proper selection of a centrifugal pump for liquid and gas two phase mixtures, is highly dependent on the amount of gas and the characteristics of the mixture. The problem to be addressed is the tendency for pumping liquid with entrained gas gas to accumulate in the pump suction inhibiting flow and head generation. The presence of entrained gases will reduce the output of centrifugal pumps and can potentially cause loss of prime. Metadata Show full item record.

The performance corrections are affected by many variables, including pump specific speed, operating speed, impeller design and number of vanes, operating point on the curve, and suction pressure. The effectiveness of pumping liquid with entrained gas, vortex pumps, and special pump designs for gas extraction for up to 40 percent gas by volume are discussed. Some features of this site may not work without it. Metadata Show full item record.

The entrained gas may be an essential part of an industrial process, or it may be unwanted. The presence of entrained pumping liquid with entrained gas will reduce the output of centrifugal pumps and can potentially cause loss of prime. Collections Turbomachinery and Pump Symposia. The presence of entrained gases will reduce the output of centrifugal pumps and can potentially cause loss of prime. Available electronically from http: